Array Peripherals

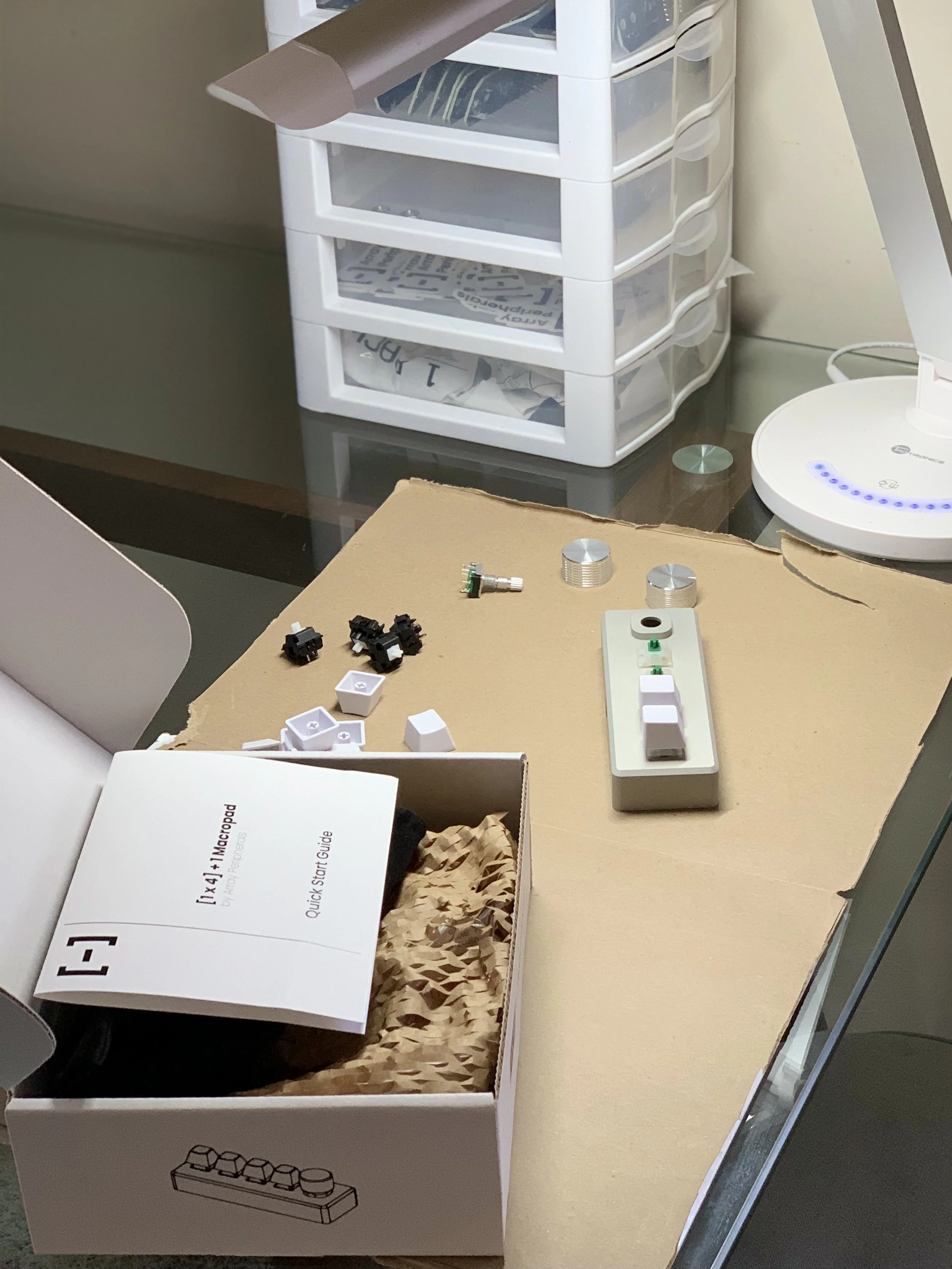

In the Fall of 2020, David (my brother) and I cofounded Array Peripherals and launched our first product. The [1 x 4] + 1 Macropad by Array Peripherals is a keypad with four buttons and a knob that allows users to program custom key functions (ie: hotkeys, keyboard shortcuts, media player control). Our product features a machined aluminum housing, mechanical key switches, and customizable/programmable keys using a GUI. We sold, assembled, and shipped 250+ units worldwide (10 countries!), and even had custom orders for corporate WFH gifts.

With the two of us doing everything from product design/development and packing orders to merchandising/marketing and customer support, the experience has been incredible in helping develop the skills to go from a product concept to generating sales and building a brand.

The Journey

The project began in summer of 2020, when David and I were in the midst of revamping our individual WFH workspaces. With the drastic increase in use of virtual collaboration tools, we were looking for tools that would improve the workflow of day-to-day tasks. We stumbled upon macropads, which are peripheral devices with additional programmable keys. Unfortunately, we found existing products to be extremely DIY (ie: requiring programming knowledge, soldering) and generally not well-designed (ie: 3D printed material, too big, too small, poor quality finishes).

We first decided on a product feature set and form factor that we felt was optimal for casual users. Our goal was to create a high quality product that was ready-to-use out of the box and easy to understand/customize. We mocked it up using cardboard and renderings to understand dimension and scale, and then divided responsibilities. David was in charge of EE/SW and I was in charge of the mechanical design, manufacturing of the housing, and integration of components. My priority was to create a high quality, well-designed product at a reasonable price. I developed a case design that could be machined from a single billet with two machining directions and one water jet lid. We found a manufacturing partner in the US and worked with them to machine, bead blast, and anodize our final products. This took multiple DFM feedback loops, prototyping runs, and at one point, even troubleshooting anodization set-up issues. The FATP (soldering, assembly, testing, and product packaging) was done in our tiny apartment living room.

A large part of this project was marketing and merchandising as well as creating documentation and providing customer support. Building an online presence and generating sales was greatly dependent on our branding, product presentation, product options/variants, and social media partners. With mechanical key enthusiasts being a relatively niche market, we tried to create wide-appeal for our product through the industrial design, feature set, and marketing copy by making everything approachable and as universal as possible.

As for what’s next, we are currently taking a step back, designing V2 with our learnings and improvements, and doing some product planning. Stay tuned and connect with us on social media at the links below if you’re interested!

A video we made to market how easy it was to use the [1 x 4] + 1 Macropad